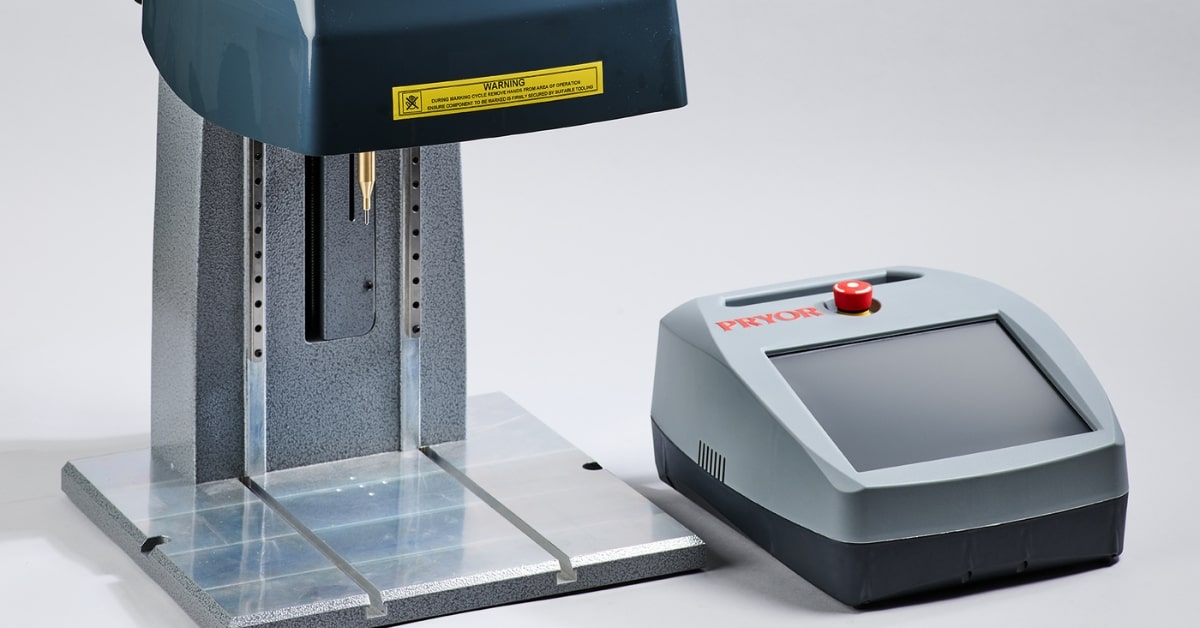

Pryor Technology have been working in the marking and traceability industry for over 170 years, so we do have ‘some’ experience in the area. Below are a collection of articles covering topics and questions that we regularly get asked. If you have further questions, please get in touch

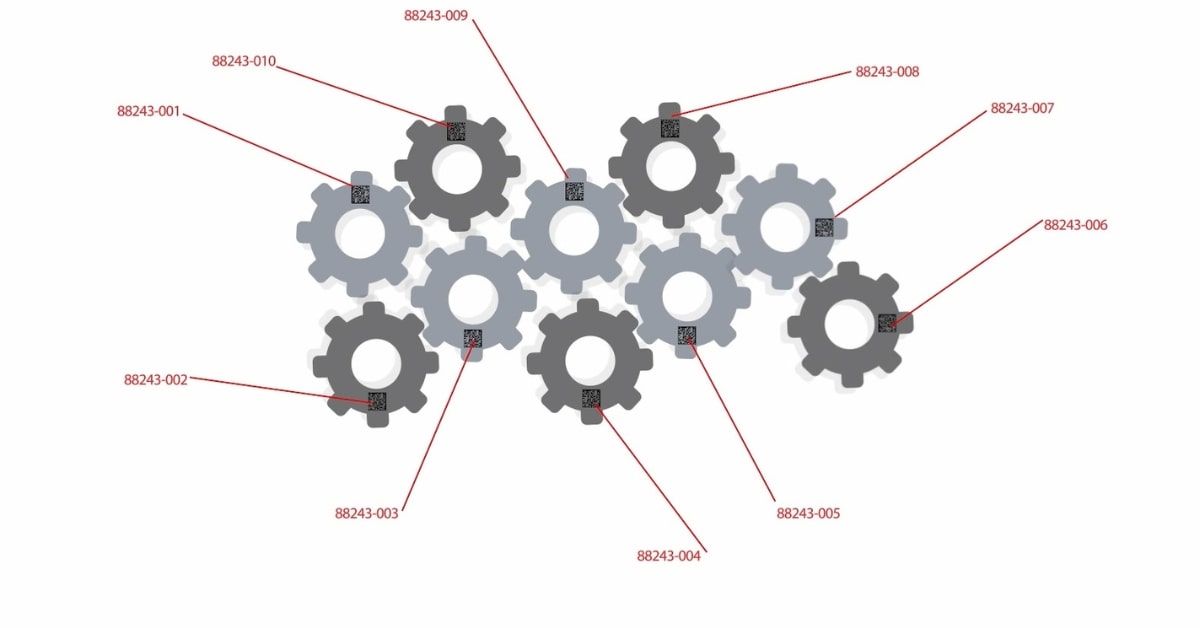

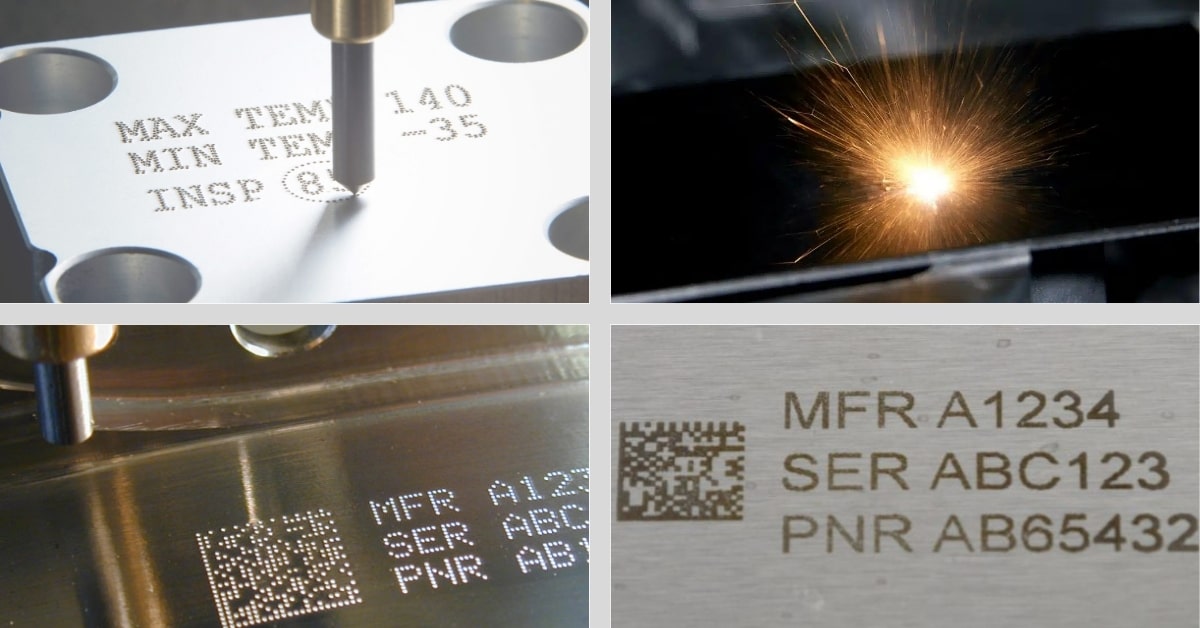

Error-proofing and Traceability

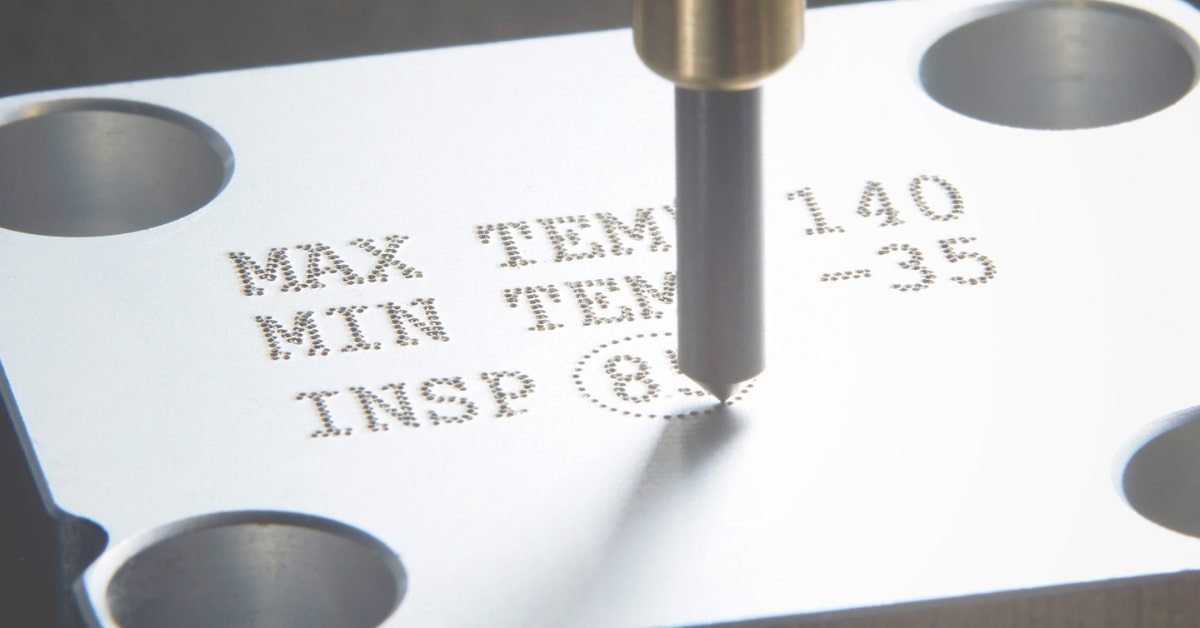

A guide to reducing quality escapes, recall costs and production inefficiency via unique part identification.