What is a Dot Peen Marking Machine?

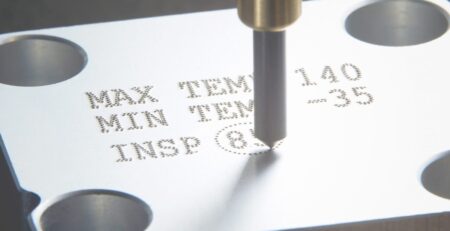

Dot Peen Marking is a method of permanently marking and identifying parts and components. Whilst these are usually metal parts, dot peen marking can be used on a wide range if different materials. A Dot Peen Marking Machine is the equipment used to apply this data, text, or logo. It uses a stylus or pin, that is fired into the marking surface to make an indented dot. By rapidly repeating this and moving the stylus between each dot, text, images, and 2D codes can be applied.

Dot Peen Marking Machines are available in a wide range of configurations to suit many applications. A simple way of differentiating the machines is to break them down into three categories:

- Portable Dot Peen Marking Machines

- Bench Mounted Dot Peen Marking Machines

- Integrator Dot Peen Marking Machines

Portable Dot Peen Marking Machines

Portable Dot Peen Marking Machines are used to mark large parts and components that are difficult to move to a dedicated marking station. They are also very useful for applications where parts need to be marked at various locations within the same site. Within the category of portable machines, there are two distinct sub-categories: those marking machines that are battery-powered, and those that require a mains power supply. Battery-powered machines obviously increase the flexibility of the equipment and make it easier to use at different locations. In recent years, All-In-One battery-powered machines have become available and offer the user a ‘battery drill’ type of product compared to the more traditional units that require a separate controller for programming and operation.

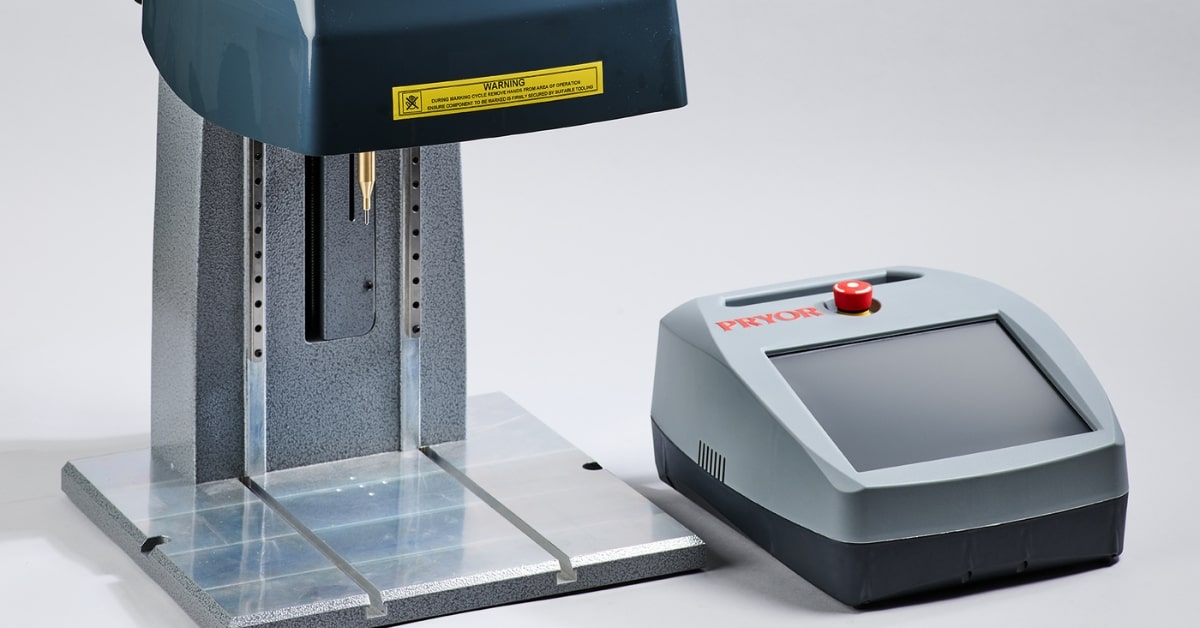

Bench Mounted Dot Peen Marking Machines

As the name suggests, these are generally standard machines that are installed on a bench or workstation. Parts are then brought to the workstation to go through the marking process. This often involves simple feed systems and part fixturing . There are a number of key features that need to be considered before specifying a bench-mounted dot peen marking machine:

- Marking Window Size – the area that the equipment can mark in

- Is a driven Z-axis (up/down) with an auto-sense feature to detect the part height required?

- Control via the standard controller or a PC-based software package

- Is a vision system required for validation or verification of the mark?

Bench-mounted machines generally offer more accuracy and give more repeatability than portable machines because there is more control over the process. Parts are secured in a fixture that is set in a certain position. This means the mark placement is as accurate as can be. The machines are generally very accurate, so control over the part position during the marking cycle is critical and can be the main factor behind any errors.

Integrator Dot Peen Marking Machines

Designed to be integrated into a dot peen marking cell and offer integration companies, and end users, the option to design and build custom dot peen marking cells that is specific to their requirements. Integrator machines are typically supplied with a control system that allows communication and connections with other equipment and networks. They are very flexible and can be used in various configurations

For examples of Integrator Machines solutions, please see our Case Study and Solutions pages

What Information Can a Dot Peen Marking Machine Apply?

Dot Marking Machines are typically used to mark:

- Human readable data,

- 2D codes (QR codes and Data Matrix Codes)

- Simple logos

Electric or Pneumatically powered

The dot peen process is generally powered electrically or pneumatically. Pneumatic machines still require a mains or battery power supply because only the marking process is pneumatically powered.

Pneumatic machines can offer a faster marking process and a deeper mark, but over recent years this difference has narrowed and electrically powered machines account for the majority of the market. This is mainly due to a low cost and a simpler installation and operation due to the lack of an air supply. Electric dot peen marking machines typically only require a standard mains power supply.

Further Information

Follow the link to view Pryor Technology’s range of Dot Peen Marking Machines

Related articles: