Pryor Technology is the Leading Manufacturer of Laser Marking and Dot Peen Marking Solutions

Pryor Technology offers hand tools, machines, and custom industrial part marking solutions.

Pryor Technology Inc is the USA Headquarters of Edward Pryor and Son Ltd, a world leader in the manufacture and design of both traditional and innovative marking, identification and traceability solutions.

Pryor Technology is the North American branch of Pryor Marking. For 30 years, Edward Pryor & Son has sold part marking solutions in the United States.

We established our offices in the United States in 2017. Since then, our US base of operations has operated in Ashland, VA. This office supports our partners and customers across the USA.

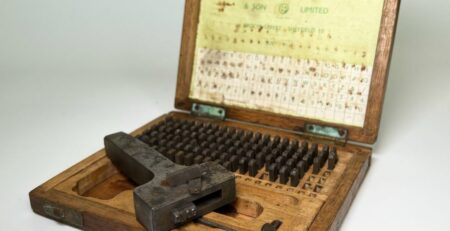

Edward Pryor & Son Ltd has built part marking machines and products since 1849. Our company has stood the test of time. But how? We provide marking and traceability solutions for all manufacturing industries.

Pryor was a family-owned business until 1978. A charitable trust now owns the company. But, we have not lost that family touch.

For more information about Edward Pryor and Son, please visit our about page.

The Latest Part Marking Case Studies and News:

Part Marking FAQ:

If you don’t see the answer to your question, feel free to call us at (804) 496-6669

What are the various marking methods and tools?

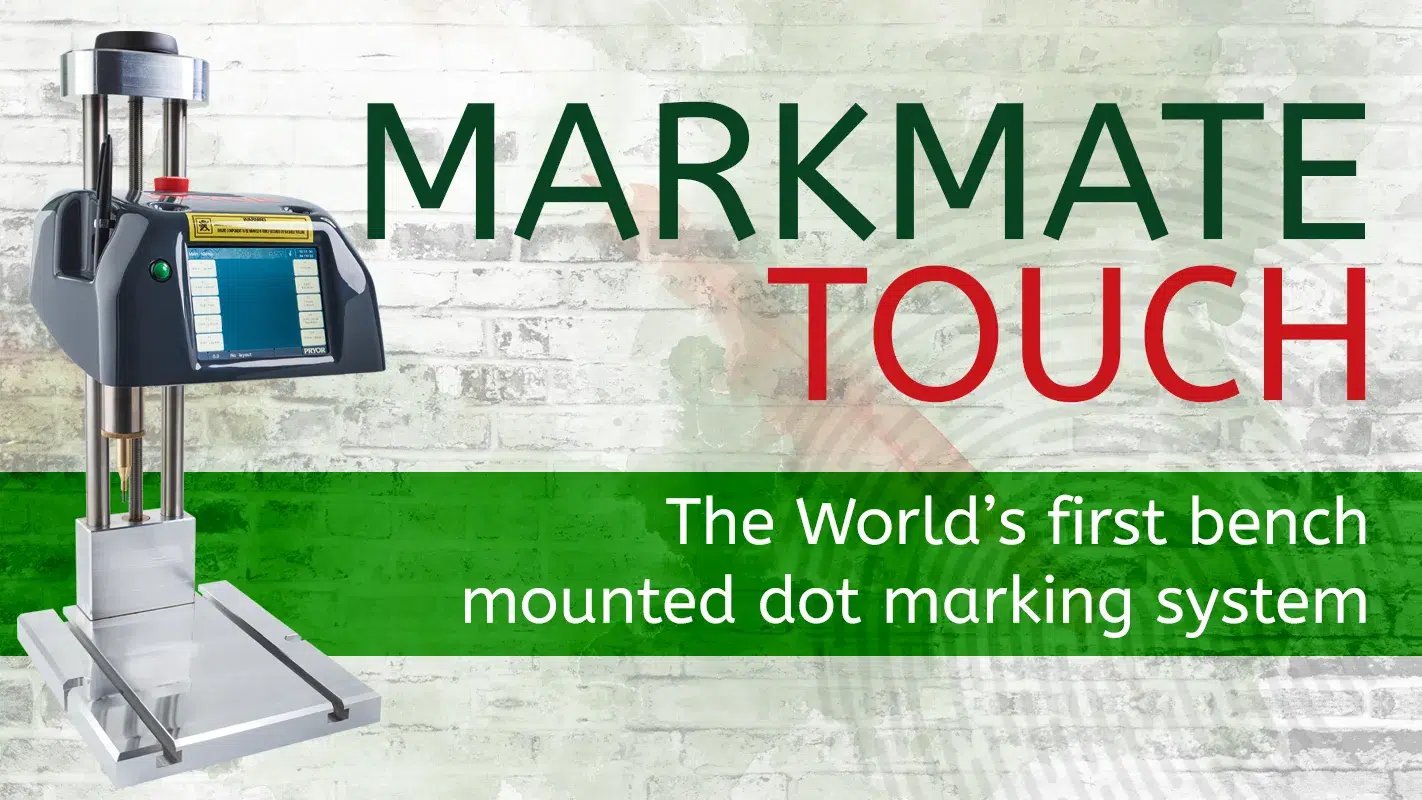

There are multiple ways to mark parts and products. You can use hand stamps on smaller projects. This method is cheaper but slower and more labor intensive. If you need to mark a part with a sequence of dots, then a dot peen machine is a good idea. Then you have engraving machines that can cut grooves into hard surfaces, chemical etching machines that remove material, and laser marking machines that use a high-energy beam of laser radiation (fiber laser), to mark the surface of materials.

Why is part marking and traceability important?

Part marking and traceability are important to optimize industrial production and ensure internal and external quality control. Marked parts can be traced throughout their lifecycle and identified should they have a manufacturing defect. This practice optimizes production and can help reduce product recalls.

What is direct part marking?

Direct part marking (DPM) is when you permanently mark a barcode on certain materials like automotive parts, aerospace parts, electronics, or other parts made of materials like glass, plastic, metal, and even leather.

What products, parts, and items require permanent marking?

Every industry is unique and has marking requirements, and every company within an industry has individual marking needs. Products big and small need to be marked, from large aerospace, automobile, and weapon parts, to small electronic and handmade items like jewelry.